Chat với Ava - Trợ lý kinh doanh AI của bạn

Xin chào, tôi là Ava, hướng dẫn viên AI giúp bạn bứt phá kinh doanh!

Cho dù bạn đang điều hành một doanh nghiệp hay đang mơ ước khởi nghiệp, tôi luôn sẵn sàng hỗ trợ bạn biến tầm nhìn thành hiện thực nhờ vào các freelancer sử dụng AI. Hay chia sẻ mục tiêu kinh doanh của bạn và chúng ta sẽ cùng tạo ra một dự án để các freelancer tài năng của chúng tôi có thể chào giá. Hãy biến tầm nhìn của bạn thành hiện thực!

Tôi đã có kinh doanh

Tôi mới bắt đầu kinh doanh

Đã xảy ra lỗi khi gửi cuộc hội thoại đến email của bạn. Hãy thử lại sau.

Bạn chỉ có thể lưu cuộc hội thoại của mình một lần mỗi giờ. Hãy thử lại sau.

Cuộc hội thoại của bạn quá ngắn. Hãy tiếp tục chat với Ava để kích hoạt tính năng lưu trữ.

How to make a prototype of your product

If you've dreamt up a physical product, developing a prototype is the first step towards building your idea into a business

4 thg 2, 2020 • 6 phút đọc

PhD Level Research, Market Research, Data Science.

Sao chép vào clipboard thất bại, hãy thử lại sau khi điều chỉnh quyền của bạn.

Đã sao chép vào clipboard.

Your prototype is the first step in taking your product from an idea to a viable business

Turning an idea into a physical product is a complex process that requires time, creativity and commitment. The design of your prototype depends on factors such as the budget you're willing to work with and your objectives for the product.

The benefits of making a prototype

Creating a prototype is significant in the sense that it allows you to critically analyze the product and test its functionality and feasibility. Also, prototyping allows you to test different materials and determine the most suitable for the final product in terms of cost, functionality, quality and durability. It also lets you experiment with different materials by building several prototypes using different materials such as steel or plastic and making comparisons. Essentially, a prototype makes it easier for people to understand your concept and highlights your professionalism when trying to explain your idea to prospective designers, manufacturers and partners.

Sketching out your prototype

One of the initial steps in transforming an idea into a physical product is putting the concept to paper for visualization (the conceptualization process). The conceptualization process not only involves refining your ideas and putting the vision down on paper to create clarity in terms of analyzing your goals and ideas for the final product, but also entails carrying out thorough market research to test the product’s feasibility.

Making a rudimentary sketch of your idea is not only a proof of concept, but is the first step towards developing your product. It's important to make several sketches from different angles in order to make necessary corrections on the sketches. Also, include the specifications of the product in the sketches, such as the design, the probable functions, the features and the materials to be used in the development of the product. If you've designed an electrical or mechanical product, include the technical details such as where to get the required parts of the product and how to develop them. Making hand sketches is also essential when filing the patent for your product, and can also be useful in the future in cases of disputes that require you to defend ownership of the product.

Digitizing your Concept

CAD and 3D Rendering

Once you're content with the rudimentary sketches and the highlighted designs, features and functionalities, the next step is enhancing the proof of concept version to a 3D non-working model. Digitizing the idea involves the creation of a draft/rough model of the product incorporating all the sketches and data. At this stage, you'll use computer tools to generate both 3D and 2D prototypes of your model.

Compared to rudimentary sketches, a 3D model is better because it's much more interactive. For example, with 3D rendering, you're able to manipulate the model in different ways including zooming, rotating and flipping to better analyze its function and design. Also, 3D rendering allows you to test the model’s performance through simulations by applying different data sets that the finished product would ordinarily be subjected to, such as heat, weather and pressure.

The creation of a 3D prototype is a crucial stage in the product development and manufacturing process, because the final product is based on the data, design and features indicated in the digital model. This makes it incredibly important that the details and specifications included in the 3D model are correct, since the digitization stage is the last step before the product goes into manufacturing.

While there are multiple tools used in creating 3D models of a product, one of the most popular tools is computer assisted designs and drafting technology (CAD). CAD enables you to evaluate the virtual model without necessarily creating the physical prototype first. In essence, CAD gives designers several advantages, such as enhancing the analysis and evaluation process, and enabling the designer to add or remove parts of the model more efficiently.

There are plenty of CAD tools on the market that are both free and subscription based, such as SolidWorks, Surface Modelers, Tinkercad, Freeware and Blender among others. CAD lets you create a virtual prototype that's a complete replica of what the physical product will be. CAD is mostly useful in 3D rendering in that it highlights the shape, dimensions and size of the final product.

Generally, a 3D rendering software program will create a photorealistic image of your product based on a compilation of digital data during the formation of the 3D object. Rendering basically transforms the technical details of the model into a visual prototype with all the features of the final product. The rendering process further includes simulations, as well as animations incorporated through 3D rendering services. Simulations and animations allow you to view the object in different angles, incorporating the focal point and other features such as shadows, colors and other related objects to give it more lifelike properties and make it appear more realistic.

The 3D rendering process involves a compilation of processes such as 3D modelling, lighting, animation and simulation, texturing, refining, rendering and delivery.

There are two main rendering methods used by CAD services: real time and offline (pre-rendered). The real time rendering method is mostly applied in models that require high speed and is mostly used in gaming applications. However, the offline or pre-rendered method is applied in objects or products in which speed is not necessarily a factor. For your product, it's likely you'll use offline rendering.

Building the physical prototype

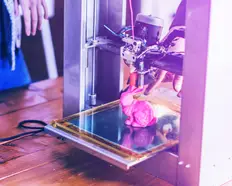

3D printing

3D printing is the final stage in creating a prototype of your product. In addition to streamlining and improving the production process, 3D printing is quite cost effective.

3D printing creates efficiency in the design process of your prototype through the application of innovative 3D modelling services that enable the production of a prototype from a single material as compared to the traditional method of assembling parts and materials to create a prototype.

With the advent of innovative technologies such as manufacture as a service (MaaS), 3D printing technology is able to support complex designs and produce quality prototypes without necessarily changing your initial idea. In essence, 3D printing boosts the production of high quality prototyping at a relatively lower price.

The decision to either build the physical prototype on your own or to seek professional assistance from 3D printing companies depends entirely on the nature of your product. For simple products, designing a physical prototype can be done using easily accessible materials at home such as used cans and plastic bottles. However, for complex products, it's crucial to take your idea to professional prototype developers to ensure that the prototype fits your standards.

There are various 3D printing services offered by professional prototype developers depending on factors such as the nature of your product, your preferred material and budget. These methods include SLA, CNC machining, vacuum casting, and metal 3D printing.

There are several crucial factors to consider when deciding on the 3D printing option. For instance, you need to take into account the cost as well as the type of the 3D printer you're selecting. Given that 3D printers vary in size, shape, quality and functionality, you need access to one that's not only within your budget, but also one that fits your product’s needs. Also, different 3D printers work with different CAD. It's important to check that the printer you select works well with your preferred CAD file format.

Lastly, check the available methods of printing as well as the printing materials that the printer supports. This is to ensure that your selected 3D printer is able to work with different materials to allow you to experiment with different options in order to determine the most viable material for your product. The most common types of materials in this case include precious metals, gypsum, nylon, ceramic, plastic and resin.

If your prototype requires the help of professional developers, it's always important to carry out extensive market research to identify the best prototyping company that fits your requirements. Ensure that the prototyping company has end-to-end prototyping capabilities, is reputable and is flexible. Also, hire a patent lawyer and ensure that all third parties involved in the prototyping process of your product sign non-disclosure agreements to protect your intellectual property.

Hãy cho biết bạn cần hoàn thành việc gì

Nhập tên dự án của bạn

Các câu chuyện liên quan

Nói chuyện với một kỹ thuật viên Co-Pilot để hỗ trợ dự án cho bạn

Các bài viết đề xuất riêng cho bạn

Hiring freelancers for a project can save you time and money, but it's important to understand how to get the best results

4 min read

If you're drawing in leads but they aren't converting, there could be a problem with the way you've set up your sales funnel. Here's how to fix it.

6 min read

Before you throw yourself into a new business idea, take a step back and ask yourself some tough questions.

5 min read

Struggling to come up with the best idea? Our exhaustive guide runs through the idea generation process to help you tap into your inner Steve Jobs.

10 min read

Cảm ơn bạn! Chúng tôi đã gửi email chứa đường link để bạn lấy tín dụng miễn phí.

Đã xảy ra lỗi trong khi gửi email của bạn. Hãy thử lại.

Đang tải xem trước

Đã cấp quyền truy cập vị trí.

Phiên đăng nhập của bạn đã hết hạn và bạn đã bị đăng xuất. Hãy đăng nhập lại.